|

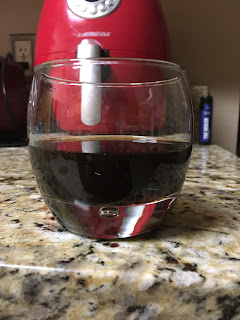

| When your beer is darker than you expected... |

UPDATE:

The Brew.

|

| 5lbs 2-row pale malt, 4oz Crystal 120L, and 4oz Chocolate malt. Here's what it all looked like after the mash was done. |

Mashed in a 5 gallon pot. Brought the water to 165F, then wrapped this pot in an old jacket and some sheets to help it maintain temperature, and let the grains steep for 60 mins. When it was done, the temp was only 114F, which seems disappointing, but the conversion must've happened pretty quickly, given my results later. I did not end up with a weak beer.

|

| The Mash - Pre-boil Wort (that's the liquid malt) |

Next, I boiled the water and added my hops. 0.5oz each of Falconer's Flight and Sorachi Ace for bittering at 60, 1 oz Saaz at 30, and the rest of my hops (another .5oz ea of FF & Sorachi) at 5 mins, along with some irish moss to help reduce trub just a bit. (That didn't work out so well; you're supposed to start the irish moss at 15 mins)

|

| The Boil |

|

| Boil complete! |

During the boil, I started my yeast with warm tap water and 1tsp priming sugar.

|

| Starting the yeast early helps increase its efficiency and effectiveness. |

You can probably start your yeast after flame-out, instead of near the beginning of the boil like I did. You really only need 10-20 minutes max to get it going; I probably had over an hour.

At flame-out, I whirlpooled about 5 minutes. That means whisking it briskly until you see a whirlpool forming, then keep going. According to Einstein's Tealeaf Paradox, whirlpooling moves the solids in any liquid toward the center, which can help reduce trub size ~ or would if I had poured properly. This also helps cool the wort faster, as it's constantly coming in contact with cooler air or the cooler sides of the pot.

I let the pot sit for 20 mins or so in an ice bath, and whirlpooled some more, to help further bring the temps down to pitching temp: around 80F.

|

| Much darker than intended. But about as expected, since i doubled the chocolate malt and forgot the Munich (red) malt. |

Once the temp got below 80, I poured it into my fermenter, an old Mr. Beer barrel that holds just over 2 gallons. These babies are awesome for small batches, and have a nice shallow pan at the bottom that helps keep the trub out of your bottles when everything's done.

Once the beer was safely in the fermenter, I poured out a sample. This thing had a ton of trub: you can see it floating in the image above! Original Gravity comes out to about 1.058 (I added .002pts due to testing at 79F instead of 68F). Assuming my Final Gravity predictions are correct, this should up my original ABV to around 5.6-5.7%, though the cool fermentation chamber may drop those numbers just a tad.

|

| The Pitch. Look at that yeast cake! |

|

| My sweet fermentation chamber! |

|

| This baby controls my fridge's temp, keeping it high enough to ferment |

|

| Extra hops should give this villainous beer a bite, and keep things interesting. |

Even as a dark ale, it shouldn't be heavy enough to be a stout, and probably won't have the body or head retention to give it that feel. I'll probably also dry-hop later on with 2oz of hops; I'm thinking Falconer's 7C's or Sorachi Ace. I expect this will be a very drinkable beer on a hot day, if not quite the refreshing Amber I was originally aiming for.

Here's the recipe:

Style:

Yield: 2 gallons

Color: Dark, Near-black

Bitterness: (TBD; too lazy to calc IBU's)

ABV: Expected 5.6-6.0%

5lbs 2-Row Pale Malt

8 oz Crystal 120L Malt

8 oz Chocolate Malt

.5 oz Sorachi Ace (60 mins)

.5 oz Falconer's Flight (60 mins)

1 oz Saaz (15 mins)

.5 oz Sorachi Ace (5 mins)

.5 oz Falconer's Flight (5mins)

1tsp Irish Moss (5 mins)

1 pkg Safale American Ale Yeast (US-05)

- Steep all grains for 1 hour, starting around 165F.

- Begin boil, add Bittering Hops. Set timer for 60 mins.

- Start yeast (around 45 mins to go), 1/2c water, 1 tsp priming sugar, set close to stove so it doesn't get too cold; covered bowl with towel to retain heat.1

- Added Saaz with 15-30 mins to go.2

- Final hop bag, plus 1tsp Irish Moss added at 5 mins3

- Remove from heat. Whirlpool for five minutes.

- Place in ice bath 30-45 mins, whirlpool for 2-5 mins, occasionally, to help bring temps down

- Once temp got down below 80F, removed from ice bath and pour into fermentation chamber. Take sample (approx. 3/4-1c liquid in a beaker). Use hydrometer to measure Original Gravity.

- Pitch yeast. Give it a good stir to break up the clumps!

- Set temp controls in fermentation chamber, and place fermenter in there.

1. You can probably start the yeast after flame-out. All you need is 10-20

2. Ideally, probably should've put Saaz in at 30

3. and Irish Moss at 15.

Now for the hard part: Waiting. I'll probably check on the temp and activity in the fermenter at least once a week. Primary fermentation should be complete in about 2 weeks; I'll probably dry hop after week one, then take a sample to see where things are at the end of 2 weeks. Once I'm satisfied with the general flavor (probably gonna be 3-4 weeks, lets be honest), I'll bottle and condition for at least two more weeks to get some good carbonation going on and complete final clean-up of the beer.

This one is going to be epic. It might take over the world.

No comments:

Post a Comment