|

| When you think you got it but you don't got it and you realize what just happened |

In discussion with some co-workers who were interested in helping fund the operation, we decided the best brew to attempt would be a chocolate orange stout! Brewing it now would allow everything to meld and mellow and the flavors to really mature and pop by mid November/early December, perfect timing for the holidays! But wait, there's more! To make this event more interesting, we decided to also brew a batch of American Pale Ale (ideally, a variation of my well-received Johnnie Flyer APA). This one would be simple, inexpensive, and only take about a month to finish. That means that when we all have to come back to bottle the chocolate orange, we'd have fresh beer to drink.

Even better: because the wife kicked my brewing operation out of the house after Darkseid inundated our entire very-poorly-ventilated dwelling with cloyingly sweet wort-smell, I've recently purchased a propane burner that works really well. Heated up the kettle super fast, but flame controls were easy to use, so I only had one boil-over.

It seemed like a wonderful plan. Then everything changed when the Fire Nation attacked...

I ordered the grain bill online. My LHBS doesn't let you grind your own grain, so you've gotta sit there and wait while they do it for you. Last time, the lady who did it offered, "Why don't you use our online form next time! It'll save you a lot of time, and the grain will be ready to pick up when you get here!" So I took her up. LHBS is almost an hour's drive from my house, but the day before brew day, I'd be in the area anyway, so I might as well make it a quick stop.

Was surprised and slightly put off that there was a $2 fee to have everything bagged separately. Because I used about 7 different types of grain over the two batches, and knew it was gonna be about $45 for the whole thing, I figured why not? An extra $2 isn't going to do much, but at least all my grain will be separated for easy use on brew day. Boy was I wrong!

Maybe I should've double-checked everything first, idk. But I trusted the shop, and didn't want to worry about grain spilling everywhere on their countertops and floors, so I just took everything home and, on brew day, opened the pack.

Everything was in one bag. What. The. Fuck. So now, my stout would be far too pale, and my pale would be much darker than it should be. This wasn't supposed to happen!

If it weren't for the 2-hour round trip, I would've made a big stink, but you gotta do what you gotta do. So, I adapted and overcame.

Whatever happens, it will be fresh beer, which will taste good, if not exactly the profile I was hoping for. And most of my crew aren't beer-picky, so they actually didn't seem to care too much. Ultimately, we spent around $70 for 7 gallons of beer* Well, let's throw it together and see what happens!

*7 gallons = 128oz x 7 = 896oz = approx. 70 bottles = approximately twelve 6-packs. Considering most craft brew is at least $10 a pack (with special holiday brews often costing upwards of $15), if this beer isn't horrible, we've saved more than $50 making it ourselves. Not. Bad. :)

----------------------

What I ended up with:

Grail Bill (total, for both brews)- 15lb pale 2-row (1.8L)

- 1lb Caramel 120L (US)

- 1lb Chocolate malt (dark)

- 1lb Chocolate malt (pale)

- 0.5lb Crystal malt 45L (C-45)

- 0.5lb Flaked Rice

- 1lb Flaked Oats

- (Total of 20lbs grain, all fucking mixed up together like a bunch of bitches)

|

| hey stormtrooper, you dropped this *makes finger circle* |

"These Aren't the Grains You're Looking For"

American, er.. Something Ale

- 7lbs "Grain Bill Mix"

- Boil Size: 4 gallons water (Final Batch Size: 3)

- 1oz Warrior Hops @ 60

- 1tsp Irish Moss @ 15

- 1oz Falconer's Flight Hops @ 5

- 1pkt Safale US-05 Yeast (made starter at flameout, pitched at 82F)

- 1-2oz -either- Sorachi Ace or Falconer's Flight @ Dry Hop, 3-4 days

- OG 1.030

- Expected OG: 1.046

Ok, the grain problem sucked, but we're gonna make the best of it, alright?? Well, shit. Second problem: the mash. I've almost always mashed on the stovetop, paying very close attention to temperature, which can be painstaking to do for an hour or longer. For Darkseid, I actually got the temp just a little high, then set the pot in the hot garage, with a couple blankets around it to hold in the heat. It didn't work very well, but I still managed to get hella high mash efficiency - probably over 85%. I've always read about using coolers. The perfect poor man's mash tun! Just clean it out, throw in the grains, then the water (at the right temp), then let it sit for an hour. So we did that, and the temp maintained itself very well. But, and I didn't realize this at the time (I probably should've done a pre-boil gravity reading like the pro's do), but this resulted in a really, really low mash efficiency! Even after sparging with about 1gal, and then squeezing the grain bag to get every last bit of wort out of it, I still ended up with an OG of 1.030, instead of target 1.046. That will make the beer much lighter, and reduce ABV by almost a full percent. We had a similar problem with the chocolate orange, 1.045 instead of target 1.071. Definitely gotta figure out what's going on with cooler mashing; should I have mashed for another half hour or so? Maybe I'll stick to mashing in a pot covered in blankets instead.

The rest of the brew for this beer, which we're gonna call Grains for short, turned out mostly ok, but not great. Took longer than expected to cool; maybe I'll need to invest in a wort chiller next? But I ended up with only about 3 gallons instead of closer to 4 that I wanted. Given how light everything was, I decided not to top it off with additional water, and to just deal with it as it was. There was also a ton of sediment despite tossing in irish moss at 15 mins; this beer is going to be full of trub.

Flavor was bready, almost like Cheerios, with very light hop aroma in the background. This will need some dry-hopping later to give it a pop. Either going with another 2oz of Falconer's Flight to enhance what's there, or 2oz of either Sorachi Ace or Lemon Drop to bring out more citrus.

Pitched the yeast at about 82F - near it's top range, I know, but it'll figure itself out - and then set it in the fermentation chamber, which will sit around 63F.

------

|

| Wife bought me a shirt with this on it a few years ago. It was clear this needed to be a real beer. |

That's No Moon

Chocolate Orange... maybeStout?

- 13lb "Grain Bill Mix"

- Boil Size: 5 gallons (Batch Size 4gal)

- 1oz Amarillo @ 60 min

- 1tsp Irish Moss @ 15

- 1lb lactose (milk sugar) @ 10

- 1oz Lemon Drop @ 5

- 8oz Ghirardelli Unsweetened Cocoa Powder @ 5

- 1oz orange zest @ 5

- 1pkt Safale S-04 yeast (pitched at 82F)

- 4oz cacao nibs, 6-8oz orange zest, 1-2oz Lemon Drop Hops (maybe) @ dry hop (3-5 days)

- OG: 1.045

- Expected OG: 1.071

Original Intended Recipe: That's No Moon Chocolate Orange Stout

Now for what we came here to do!

The goal of this beer was to have a dark (chocolate milk) stout with very, very obvious chocolate up front, but also a ton of orange. I want it to taste like a holiday dessert - a Terry's Chocolate Orange! Maybe I can convince my wife to try one (she hates beer). The decision to make a chocolate orange came from the group. I had a couple ideas for Christmas ales, all dark and stout/porter-ish, and one of the guys was all, "Dude. What about a chocolate orange?" We were sold. Took a lot of research to develop the recipe; not many good chocolate orange stout recipes are out there, and most that are tend to be very weak on the orange, or rely on chocolate malts for the darker semi-chocolate flavors, so my research went into intensely chocolate stouts (of which there are many proven recipes), and research into how people use orange in different beer varieties. The consensus seemed to be: cocoa powder and some orange zest at the end of the boil, and cacao nibs plus a ton of zest during dry hopping. Additionally, hops that will bring out a bit of an orange flavor, or a stronger citrus (but closer to orange or lemon than grapefruit or flowers) would be a great idea for this one, so we chose Amarillo and Lemon Drop.

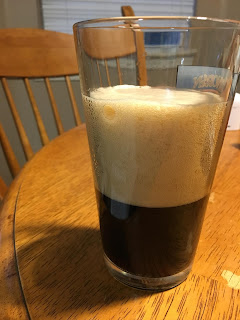

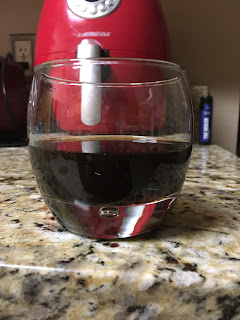

The brew for Moon went a little better than Grains, though with the same really poor gravity results. While the mash was far paler than a stout should ever be, that chocolate did real justice hiding that fact! This one came out looking like chocolate pudding, and a strong chocolate flavor on top of a biscuit. Like a chocolate biscotti! Practically no hops or orange flavor (just a tiny hint in the background), but that's to be expected with so much chocolate in there. Oh, and only 1oz of zest?? Yeah... I bought clementines because we decided zest from sweet oranges would work the best, but did you know it's a pain in the ass to zest clementines? Whatevs; the kids love them so they won't go to waste. I'll probably buy a bunch of regular, larger sweet oranges for dry hopping. The hops should come more forward later, too. Amarillo for bittering and Lemon Drop for aroma, should give it that orange-citrus feel, and I may add another ounce or two of lemon drop during dry hop stage (3-5 days, about two weeks before bottling time). I also expect the cocoa flavor to die down over time, so 4oz of cacao nibs will go in at the same time as everything else, to keep everything gooey chocolatey. It just means I need to up the ante with orange & hops a bit. Worst case scenario, I'll end up adding a pinch of orange zest to each bottle to ensure everything pops - a labor-intensive act, but a labor of love for a Christmas batch. Plus, I should be able to get the crew back together; bottling day with a group will be hella faster and less slow and boring than brew day was.

----

Epilogue

Well, some things didn't go as intended, but I think overall, we're going to end up with 7 gallons of delicious beer, and possibly even a new idea for recipes, if this goes well. Everything is a learning experience, and this is the first complex beer I've made in like 5 years, second beer period since moving to Florida. You can't win them all, but most beers can be recoverable, and the important thing is to learn and improve!

Oh, and I almost forgot: We had a bunch of the remaining Darkseid yesterday, including the two cold brew coffee variants I made (those sat in the fermenter for about 2 months). Turned out fucking delicious. Was compared favorably to Duclaw Brewing's Sweet Baby Java, which makes me very happy. I will be doing a larger cold brew stout or porter batch based on this recipe in the future.

I'll update when These Aren't the Grains You're Looking For is ready to drink, probably about a month from now.